Objective

Delta Electronics, founded in 1971, is a global leader in power and thermal management technologies, providing smart energy-saving solutions across e-mobility, industrial automation, building automation, ICT infrastructure, and energy infrastructure. To sustain high production volumes, Delta has undertaken significant smart manufacturing initiatives at its production bases to enhance efficiency, flexibility, quality, and sustainability.

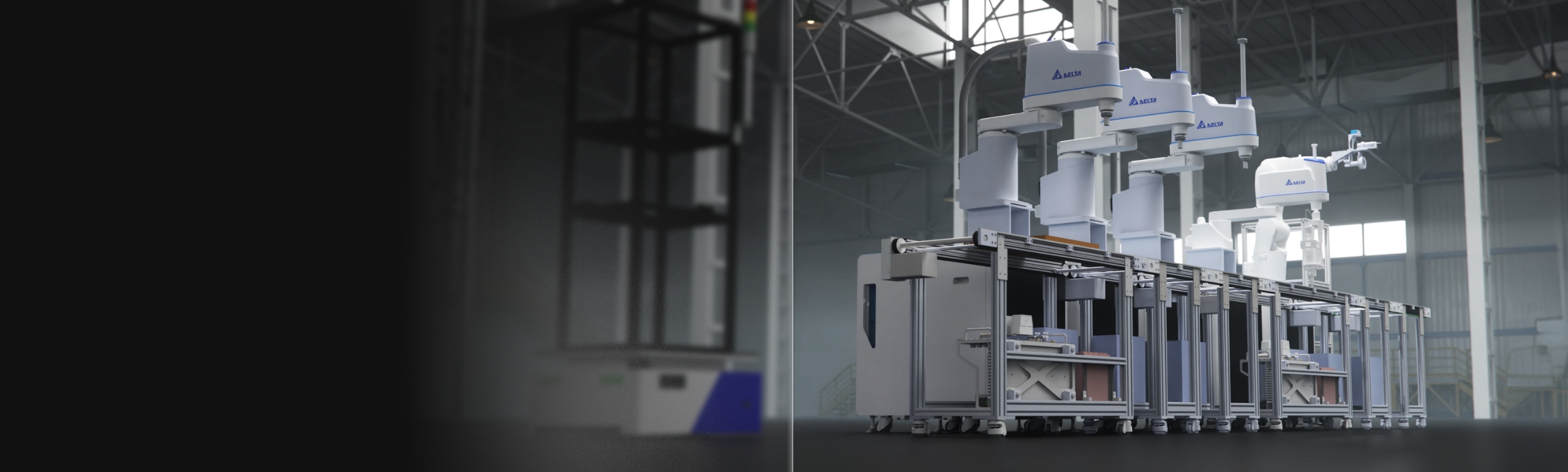

Using NVIDIA Omniverse™ and Universal Scene Description (OpenUSD), Delta is virtually linking specific production lines, aggregating 3D data from a diverse range of equipment to create a digital twin. Then, with the NVIDIA Isaac Sim™ simulation application, Delta generates physically accurate, photorealistic synthetic data for training their computer vision models and simulating the performance of their inspection cameras. This lets them optimize every part of the factory process before actual production starts.

Customer

Partners

Use Cases

Robotics

Computer Vision/Video Analytics

Simulation/Modeling/Design

Products

NVIDIA Omniverse Enterprise

NVIDIA Omniverse Replicator

Universal Scene Description (OpenUSD)

NVIDIA RTX Virtual Workstation

NVIDIA Isaac Sim

NVIDIA RTX A6000

NVIDIA RTX A40

With Omniverse, Delta is realizing major benefits including:

- Reduced production downtime by using synthetic data to bootstrap the training of computer vision models.

- Increased production efficiencies by identifying and addressing production line issues with digital twin simulations.

- Improved collaboration by centralizing all 3D assets from disparate sources with OpenUSD.

- 100X faster AI training with synthetic data

- 90% object model detection accuracy with synthetic data

Optimizing Production Lines With Simulation

Delta frequently changes and reoptimizes its production lines based on the components and products they need to manufacture for their customers. To achieve this across an incredibly complex, fast-moving electronics assembly line for assembling power supplies is no easy feat. Their team connects machines in the production line, then uses mockups and static images to identify and remove physical collisions, issues, and errors.

However, this approach relies on position switches to detect trays and objects on the production line. When the number of robots and machines increased in their production lines, Delta needed to add more position switches. This wasn't scalable or suitable to accommodate their need for flexible production, as it took more than 30 minutes to reconfigure each position switch, resulting in costly production downtime whenever the layout needed to be changed.

To address these challenges, Delta built a physically accurate digital twin of their production lines. This allowed them to iterate much more quickly on reconfiguration and run multiple “what-if” simulations to identify optimal line designs.

Another key advantage of a digital twin was the ability to rapidly generate synthetic data at scale to test and train highly accurate computer vision models for detecting trays and products in the production line. This new approach allowed the team to greatly accelerate the production planning process, as they no longer relied on reconfiguring every position switch.

Delta Electronics

A Unified Asset Pipeline for Building Digital Twins

The process of creating a digital twin begins with aggregating and visualizing 3D assets from the environment. Delta uses multiple 3D applications, including Autodesk 3ds Max, FlexSim, and Visual Components to model and simulate their production line. Historically, it would be nearly impossible to bring data from these modeling and simulation tools into one environment without time-consuming data transfer, model decimation, and interoperability hurdles. Even then, once the data is aggregated, if any changes are made to models or processes in the source 3D applications, the process of aggregating starts again to update any changes.

With Omniverse, Delta can connect their various applications and data together using a unified asset pipeline, allowing their teams to visualize and collaborate on the entire output in a single environment. This is all made possible by OpenUSD and additional connectors and extensions that allow third-party tools to feed live data into a USD stage through a Nucleus server.

Once all the assets are aggregated in the digital twin, the Delta team can run simulations and identify issues early in the design and reconfiguration process, well before making changes to their physical production lines. This is key to avoiding costly downtime and change-order requests.

"When apps connect to Omniverse, this allows all our files and data to be synced simultaneously, so team members can see updates in the USD Stage and collaborate in real time," said Ares Chen, PSBG General Manager at Delta Electronics. "USD enables seamless collaboration with each team member, so we can design a production line faster and more efficiently than before."

“Using Isaac Sim and Omniverse Replicator has allowed us to significantly increase our synthetic data generation capabilities by over 100X, compared to previous methods of training. This greatly increases efficiencies and ultimately accelerates our designs of new production lines.”

Ares Chen

PSBG General Manager, Delta Electronics

Delta Electronics

Accelerating Industrial Inspection With Synthetic Data

Delta uses computer vision for automated inspection in the final assembly, checking for issues like missing components or misaligned screws. AI-assisted Automated Optical Inspection (AOI) significantly accelerates the inspection process, enabling Delta to detect defects early and minimize the need for manual intervention.

Delta faced a challenge in training AI models because collecting and labeling data manually took a lot of time–up to two days for 1000 images. To speed things up and cut costs, they switched to using synthetic data with Omniverse Replicator. Now, in just 10 minutes, they can generate the same amount of labeled images that would take two days manually.

The team also achieves a 90% accuracy with synthetic data, similar to real data. The big win is that they reached this accuracy level in just a tiny fraction of the time it usually takes to collect real data—now done in one-hundredth of the time. This not only accelerates AI training, but also makes the process more cost-effective and efficient for computer vision applications.

Delta also uses NVIDIA Isaac Sim—a scalable robotics simulation application—to accurately simulate the performance of the model and detect the position of a tray in the production line.

By creating the digital twins in Omniverse, Delta can minimize downtime and reduce risks while reoptimizing production lines.

Start developing interoperable 3D workflows and OpenUSD applications.